Compaction Performance of Clay Stabilized with Cement and other

ABSTRACT

Concrete is the most commonly used binding agent for stabilization and hardening purposes in the field of civil engineering. Unfortunately the production of cement requires an energy consuming procedure. By considering that a massive amount of warmth is released from bare cement production, it is essential to find a better or a partially alternative to bare cement in construction. Soil stablizing with cement plays a role in global warming as the production of cement generates carbon dioxide. In this paper, lab experimentation was carried away in order to check out the effectiveness of cement, mica powdered and silica sand as materials to stabilize clay for construction purpose. Inside such case, mica natural powder serves as a partial alternative of cement to reduce cement consumption for soil. Stabilization and compaction. This particular study concentrates on the functions of mica natural powder as a pozzolanic component, silica sand as for filler injections, and cement as water balance agent in increasing the compact ability of the stabilized soil. The compaction test with standard Proctor effort was performed on the clay specimen and the stabilized soil with various mix designs in order to identify a suitable dosage of binding for the clay leveling. The result shows that briciola powder can be beneficial for cement-soil stabilization for the reason that it reduced the ideal water content and increased the utmost dry density of the clay. This results in a discount of air void content for the soil.

INTRODUCTION

Cement is the most commonly used joining agent for cementation and stabilization purposes in city engineering. Every year, a significant amount of concrete is produced for building purpose. Production of bare cement is energy consuming, due to the fact a massive amount of heat is required for their production. This research adds to global warming as the production of concrete generates carbon dioxide. In the field of soil leveling, it is well founded that lime green can be used as a backing agent to increase the executive properties of clay as foundation soil. Nevertheless , the process of lime stablizing is time consuming credited to its pozzolanic impact in nature. Considering the fact that time efficiency and cost saving in construction projects are of great importance, there is an urgent need to research on suitable materials for the stabilization of clay. In this papers, Standard Proctor compaction assessments were carried out in order to look at the effectiveness of cement, mica and silica sand as materials to stabilize clay for ground improvement purpose. The clay of red in color was obtained from a construction site near by Infrastructure University Kuala Lumpur (IUKL) in Kajang, Selangor, Malaysia. The clay has a certain gravity of 2. 71, plastic limit of 18% and liquid reduce of 38%. It is classified as CLAY of intermediate plasticity.

This research work explored the compactability of mica powder as a pozzolanic additive, silica sand as filler, and cement as a water balance agent in the stable soil admixture. With value to that, the compaction properties of the sits firmly soil were investigated in order to identify a suitable stabilized soil admixture for the clay leveling. It is noteworthy to emphasize the positive properties of mica powder making the material a suitable ingredient to partially replace cement for soil stabilization. Mica is a group of sheet silicate (phyllosilicate) nutrients which includes several related materials which may have an almost perfect basal cleavage with crystal appearance. In this research work, mica in powder form is utilized as a soil pore refiner to partially affect the cement in stabilized clay. Typically the characteristic which makes micas useful for soil leveling is that it possesses an excellent combo of chemical, power, physical, thermal and mechanical properties that are not found in many additives. Briciola is a complex hydrous silicate of aluminum that contains potassium, iron, magnesium, salt fluorine and/or lithium and also traces of several other elements. It is secure and completely inert to the action of normal water, acids (except hydro-fluoric and concentrated sulphuric), alkalis, standard solvents, and oils which are practically unaffected by atmospheric action.

Mica is a phyllosilicate mineral with a common basic very structure, platy morphology and perfect basal cleavage (Fleet, 2003). Micas are broadly classified as true micas that include minerals such as muscovite and fragile micas that is included. Aside from the standards of mica mentioned above, mica is categorized as silicate type of soils, and soils with silicate characteristics enhance the effect of cement on soil treatment. The content of free mica minerals in tiny rocks, particularly muscovite, is reported to significantly affect such engineering properties as plasticity index, compacted density and strength. Apart from this research work, there is no published work that explores the use of mica as a pozzolanic additive of stabilized soil. With high silicate content in granello, there is a great potential for it to enhance the engineering properties of cement stabilized soil such as plasticity index, compacted dirt density and strength. Within their compaction study of micaceous soils, Ballantine and Rossouw (1989) learned that the soils are hard to compact because of their high demand of moisture happy to achieve maximum dry denseness. On the other palm, an experimental investigation on the characteristics of the sand blended by Clayton et al. (2004) demonstrated that mica content boosts compressibility of soils, thus by adding 10% or more of mica content to sand could lead to appeasement of any dilation, and a weak un-drained shear power. It was mentioned by the authors that mica particles cure the gap ratio and create a low dry density. Sowers (1954) believed that the higher the mica content is in the micaceous soil, the greater is the maximum dry denseness, because of the retaining water capacity of mica (Sowers, 1954). He found that the range of the the best moisture content of a micaceous soil with high mica content is normally between 12% and 35%. Generally, it was noticed in the findings that the higher the mica content, the greater is the soil optimum water content. The main point of outcome of the study finding is that the lower mica and kaolinite content in the soil, the lower maximum dry denseness of the soil is resulted (Sowers, 1954, 1963, 1983).

Mica is a phyllosilicate mineral with a common basic very structure, platy morphology and perfect basal cleavage (Fleet, 2003). Micas are broadly classified as true micas that include minerals such as muscovite and fragile micas that is included. Aside from the standards of mica mentioned above, mica is categorized as silicate type of soils, and soils with silicate characteristics enhance the effect of cement on soil treatment. The content of free mica minerals in tiny rocks, particularly muscovite, is reported to significantly affect such engineering properties as plasticity index, compacted density and strength. Apart from this research work, there is no published work that explores the use of mica as a pozzolanic additive of stabilized soil. With high silicate content in granello, there is a great potential for it to enhance the engineering properties of cement stabilized soil such as plasticity index, compacted dirt density and strength. Within their compaction study of micaceous soils, Ballantine and Rossouw (1989) learned that the soils are hard to compact because of their high demand of moisture happy to achieve maximum dry denseness. On the other palm, an experimental investigation on the characteristics of the sand blended by Clayton et al. (2004) demonstrated that mica content boosts compressibility of soils, thus by adding 10% or more of mica content to sand could lead to appeasement of any dilation, and a weak un-drained shear power. It was mentioned by the authors that mica particles cure the gap ratio and create a low dry density. Sowers (1954) believed that the higher the mica content is in the micaceous soil, the greater is the maximum dry denseness, because of the retaining water capacity of mica (Sowers, 1954). He found that the range of the the best moisture content of a micaceous soil with high mica content is normally between 12% and 35%. Generally, it was noticed in the findings that the higher the mica content, the greater is the soil optimum water content. The main point of outcome of the study finding is that the lower mica and kaolinite content in the soil, the lower maximum dry denseness of the soil is resulted (Sowers, 1954, 1963, 1983).

METHOD OF SETTING

Common Proctor Compaction method determined by ASTM D 698 was utilized for performing compaction tests on both neglected and stabilized clay individuals. According to the method, the soil was compacted in three equal tiers by using a rammer with a weight of 2. 5 kg. The rammer was repeatedly dropped at a height of 310 logistik for 27 blows on each compacted soil coating and the tests were repeated for various dampness contents. Using the results that show a variety of dry thickness over the corresponding drinking water content, the maximum dried out density and optimum drinking water content were determined for the soil specimen. Stand 1 summarizes the mix design of both untreated and stabilized clay specimens with various percentages of the soil, silica sand, bare cement, and mica powder. That is seen from the table that the granello content was varied in each mix design as a partial replacement of cement in the stable soil. The best blend design of the stable soil was determined on the basis of the highest maximum dry thickness in compaction.

RESULTS AND DISCUSSION

The compaction results in term of maximum dry density and optimum water content for the test specimens in line with the specified mix designs are summarized in Table 1 . The graphical plots that show the relationship between dry density and normal water content for the dirt compacted in accordance to the specifications of the mix designs are illustrated in Figure 1. With no treatment, the compacted clay example of beauty has a maximum dry density and optimum drinking water content of 1665 kg m-3 and 17. forty percent respectively. By comparison, the maximum dry density and optimum water content increased by 8. 47% and decreased by 8. 05% respectively when the condensed soil was partially substituted with 20% silica crushed stone and 20% cement as shown in mix design A. This is affordable as the inclusion of silica sand increased the soil density and the incorporation of cement advertised hydration process that reduced the soil optimal water content. In such circumstance, the effect of binding from the hydration effect improved its compact ability. It must be highlighted that silica sand performed as filler in the cement stabilized clay. Typically the role of silica crushed stone as filler in stable soil is also recorded in the published works of Wong et 's. (2013a), Wong et 's. (2013b), Wong (2014), Wong (2015a) and Wong (2015b).

If the cement contents of the stabilized clay individuals were partially replaced with mica powder ranging from 1 to 5%, the maximum dry density of the stabilized clay was found to vary from 1647 to 1827 kg m-3. The greatest compaction was achieved by a test specimen with mix design C which has a highest maximum dry density of 1827 kg m-3. Such finding provides an indication that 2% part replacement of the cement with mica powder resulted in the greatest providing effectiveness of the compacted test specimen. This is partially caused by the fineness of mica powder that filled up the pore spaces, thus minimizing its void ratio in the process of compaction. In a similar fashion, Mousavi and Wong (2015) found that a partial replacement of cement with peat ash was effective at enhancing the compact ability and shear strength of stabilized clay. Considering these facts, combine design C is justifiable as the best combine for the application of compaction of the clay-based.

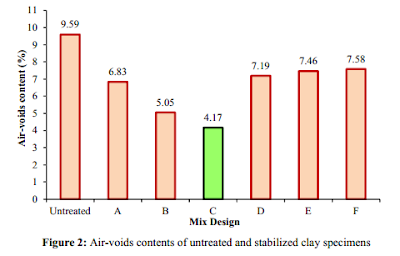

The degree of compaction for the test individuals can even be gaged on the basis of its air-voids content. For that purpose, the relationships between the air-voids content and the mix designs of the compacted test specimens are shown in Figure second . The air-voids content is the ratio of the air-voids volume to the specific volume of the soil (Whitlow, 2001). It is very important note that the ultimate goal of compaction is to reduce the dirt air-voids volume, thus lowering its susceptibility to volume change. It is apparent in Figure 2 that compaction of test specimen with mix design C resulted in the least expensive air-voids content of 4. 17% when comparing its compaction effect with other mix designs as specified in Desk 1. This really is steady with the compaction results of Table 1 and Figure 1 which show that compaction of test example of beauty with mix design D resulted in the greatest maximum dry density of 1827 kg m-3. These kinds of finding supports the validity of the justification that mix design C is the best mix design for the application of the clay compaction. Typically the result signifies which a put together effect of cement hydrolysis and pore refinement of soil by mica powdered contributed to the finest packing implication of the soil due to compaction when compared to the test specimens compacted with other mix designs.

CONCLUSION

It can be summarized that mica powder has a good effect as partial replacement material of cement to enhance the compact ability of clay. Based on the research findings, it can be concluded that standard compaction of the ground with mix design Chemical (60% soil, 20% silica sand, 18% cement and 2% mica powder by dry weight) resulted in the highest dry denseness improvement and air-voids content reduction when compared to the ones from the test individuals compacted at other blend designs. Overall, this is attributable to the mixed functions of cement water balance, pore refinement of granello powder and silica fine sand as filler that activated binding effect on the compacted soil.

ACKNOWLEDGEMENT

The writers would like express their sincere gratitude to the Ministry of Education (MOE) of Malaysia for money the investigation through Exploratory Research Grant Scheme (ERGS) (Project Grant Number: 13012013ERGS).

REFERENCES

- Ballantine, R.W. and A.J. Rossouw (1989) “Stabilization of soils,” Pretoria: PPC Lime Ltd, pp 25–27, 42–51.

- Clayton, C.R.I., M. Theron and N.J. Vermeulen (2004) “The effect of particle shape on the behaviour of gold tailings,” In Advances in geotechnical engineering: The Skempton conference, Thomas Telford, London (pp. 393–404).

- Fleet, M.E., W.A. Deer, R.A. Howie and J. Zussman (2003) “Rock-forming Minerals: Micas, Volume 3, Part 1 of Sheet Silicates: Micas,” Geological Society of London.Vol. 20 [2015], Bund. 28 13548.

- Mousavi, S. and L.S. Wong (2015) “Utilization of brown clay and cement for stabilization of clay,” Jordan Journal of Civil Engineering 2015;9:163-174.

- Mshali, M. and A.T. Visser (2012) "Influence of mica on unconfined compressive strength of a cement-treated weathered granite gravel," Journal of the South African Institution of Civil Engineering 54(2): 71-77.

- Sowers, G.F. (1954) “Soil Problems in the Southern Piedmont Region,” Proc., Atlanta convention, Atlanta, GA, ASCE Vol. 80, Separate No. 416, pp. 1-18.

- Sowers, G.F. and T.L. Richardson (1983) "Residual soils of Piedmont and Blue Ridge," Transportation Research Record 919, Transportation Research Board, Washington-DC, pp. 10-16.

- Sowers, G.F. (1963) "Engineering properties of residual soils derived from igneous and metamorphic rocks,” Proc., 2nd Panamerican Conference on Soil Mechanics and Foundation Engineering, Sao Paulo, Brazil, pp. 39-62.

- Whitlow, R. (2001) “Basic Soil Mechanics,” Pearson Education Limited, 4th Edition.

- Wong, L.S., R. Hashim and F. Ali (2013a) “Utilization of sodium bentonite to maximize the filler and pozzolanic effects of stabilized peat,” Engineering Geology 152:56-66.

0 Komentar:

Post a Comment