The Cemented Filling Technology exploitation Special Filling Road in Gob

Yang Baogui

Associate Professor

Faculty of Resources and Safety Engineering, China University of Mining and Technology

e-mail: baogui@cumtb.edu.cn

Du Xueling, Dang Peng, Zhang Kaifang

ABSTRACT

The thesis studies the arrangement in coal mining panel by victimization special filling route to fill mining, theoretical basis, capability and then on. supported the realistic circumstance of mine filling technology, we have a tendency to believe the hydraulic support required to be employed in trendy filling technique however the yield of the coal is thus low. it's tested possible to use the special filling route in mine in keeping with the idea of the movement of the superjacent strata in mining panel. New technology is mentioned within the condition of high coal caving mining technology space. It’s reckoned that one.0692 million t/a production are obtained with the new technique. therefore the new technique is possible each in technology and economy.

In recent years, several mines were crammed with colourful mining apply. Gob cement filling could be a technology that mixes with AN applicable quantity of building material material coal gangue, ash and different materials, mixed with water and stir into filling suspension, and so transported by pipeline to gob. suspension off excess water in gob and forms a form of filling body suspension that contains a sure strength, integrity and independent. totally {different|completely different} cemented filling strategies area unit different within the use of materials, liquid characteristic aspects of the rate of flow vary, truth concentration, filling tube diameter, preparation characteristics, special needs, applicable conditions and different aspects the present coal mining filling technology typically contains a lower coal production. This paper presents found out a special filling route, from the innovation of filling mining method to explore the feasibleness of up fill mining technique of production.

EXISTING GOB CEMENT FILLING

MINING TECHNOLOGY

Existing gob cement filling mining technology

CoalModern coal cemented filling mining technique includes paste filling, like cream filling, high water material filling, high concentrations of cement filling and different forms[1-2].

Paste filling mining technique is to create mine tailings waste dump gangue, poor-quality soil , plant ash and different solid waste within the ground into a paste suspension, delivered to underground mining face by high-density solid filling pump or through the pipeline by gravity beneath the action of a pump, timely filling the gob. Paste Filling suspension concentration reaches eighty one ~ half of one mile, an enormous time investment, transportation technical is tough, and vulnerable to blocked tubes accidents. Even with patterned paste filling to avoid wasting prices, the direct value of coal continues to be sixty five yuan / t, Panel capability of annual production is regarding 300 000 t / a [3-4].

Like paste filling is that the use of building material materials, use mines, power plants industrial waste (such as tailings, coal gangue, ash or stream sand, etc.),for mixture, the combination with appropriate fine grade ingredients, the suspension fabricated from the mass concentration of seventy two to seventy eight, and also the look seems like a paste. Like paste backfill strength near the strength of the paste backfill, however the backfill desires underground dewatering, touching panel production [5-6].

High water materials unremarkably used the fabric that the water volume share is larger than ninety fifth, build the A and B materials delivered to the underground space crammed through completely different channels, the formation of mixed backfill has sure intensity. victimisation this technique, filling body strength cannot be secure once loss water within the late, and transportation of 2 materials is separate, it makes the pipeline advanced. Single Panel highest yield no over one hundred,000 t in sensible applications, creating the value per ton attributable to a rise of regarding sixty six.92 yuan whereas filling jobs, accounting for twenty two.5% of the whole value per ton of coal mining for the filling, additionally, there's conjointly crammed with high choose incomplete and different problems [7].

High concentrations of cement filling is filling technology refers to the gangue powerhouse ash and different solid materials and cement, and atiny low quantity of water as a filling material, through the activation of agitation, which is able to prepare the filling suspension into a high concentration suspension and sent to the underground gob by drilling, pipeline. Since the mixed suspension area unit customary dispersion having thixotropic properties, a high content of fine fraction material, greatly multiplied specific surface plot, beneath vigorous stirring, the mixed dispersion of solids within the suspension is diluted liquid, and then that produces the cement particles equally distributed. typically speaking, the important mass concentration of high concentration suspension filling is seventy four to eighty two slump within the two hundred ~ 240mm. Cement filling the body of this method, grain size and cement in distribution, no coarse and fine particle stratification, sensible filling body integrity and stability, straightforward pumping; high filling body strength; no would like or simply to a small degree dehydrated. Compared the high concentration cement filling with paste filling, attributable to the high concentration of filling suspension flow is sweet, a lot of causative to filling the highest choose, therefore dominant surface subsidence result is right. additionally, in terms of internal control and delivery, the high concentration suspension filling a lot of convenient, low chance blocked tubes events occur, sensible stability and responsibleness of the system, and also the modest investment in instrumentality. High concentrations cement filling is obtaining a lot of and a lot of attention attributable to its suspension flow is sweet, filling body is simple to select first-rate and ideal aerofoil subsidence effect[8].

In addition, existing gob filling mining typically need filling with special brackets that applies beneath sure special conditions. Its application vary is said with specific geologic conditions and also the choice of filling materials. Special filling brackets would like freelance style, specializing within the production and also the follow-up applied to non -filled panel remains unclear, thus it's not solely increase prices, however will cause the tube waste[9]. once victimisation the special brackets in backfill mining, filling panel and stope area unit at constant level, each mutual interferences, it's tough to attain operation.

The main downside existing in filling in gob

Current gob cement filling has the subsequent issues. First, the filling capability of the filling system cannot meet the requirements of mine filling; Second, the gob fill and activity of filling suspension need to take a extended operating time, is can have an effect on the conventional production in panel. Third, the coal mining and filling operations cannot be achieved severally of every different in operation. By coming up with and victimisation special filling tube has retractile roof beams will defend filling body, at the same time cutting coal work, so as to attain activity time of filling suspension and mining time in coal panel coincide, it will shorten the natural process time occupied, and contains a substantial increase in mining time, and ultimately to boost the assembly capability of the operating face. however special brackets simply to attain an exact degree of balance between mining and also the filling job, and didn't fully solve the contradiction between the 2. And it's not possible to boost the flexibility of the filling system during a short time. Therefore, there's a requirement for technology innovation to fill mining technique to boost the present filling capability from the facet of technology advances.

LAYOUT OF SPECIAL FILLING ROAD IN GOB

Arrangement of special crammed route

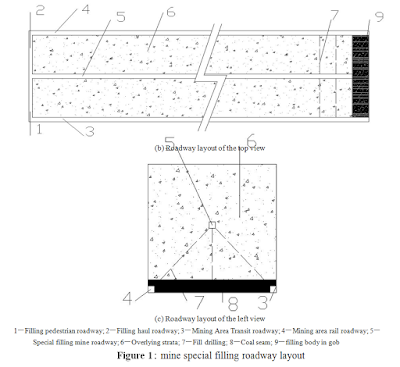

Shown in Figure one, within the mining space, organize transportation route and rail route on strike direction. On high of operating surface overburden central dig a route parallel to the direction of the coal strike, the route is found higher than steady the rock of seam, this is often the special filling route. The route floor layout of the 3 drilling parallel to the panel length direction, every drilling direction varies to confirm that the direction of the every borehole is equally distributed within the dip direction of the operating surface. It is able to ensure the filling body fills up the whole gob fully. looking on the circumstances, is organized AN Inclined Lane for pedestrian and transport materials within the neck of the woods of the column in coal mining space, also can be separate dig a filling pedestrian route and a filling haul route from the mining space. once victimisation multilane layout, it's useful to boost the work atmosphere within the special filling route.

The shear physics take a look at was administered by the tactic of dominant shear rate. we have a tendency to place the rotor at five hundred metric capacity unit beaker once testing with the shear rate of rotation which may be amendment. we've got done persistently proportioning and several other times to induce a mean price to eliminate the measure error. Record the corresponding shear stress and apparent viscousness values once theexperiment, the vary of shear rate is 0~120 s-1,Last time is a hundred and twenty s. Madethe preparation of 4 #, 5 # and half-dozen # suspension samples in keeping with table four set quantitative relation and pour it intorheometer in barrel to hold out the physics experiment of stowage suspension. to investigate the experimental information and process by laptop code matched with rheometer so as to induce the corresponding suspension physics parameter.

Special filling route layout basis

- There could be a comparatively stable rock higher than the operating surface. once the tunnel excavation, the superjacent strata bit by bit hanging condensation. With the panel progresses, superjacent strata movement on the longitudinal direction is usually administered from the lowest. once the lower strata reach an exact bent settlement, the gradual separation and injury occur. however within the method of mining panel, rock department on high of immediate roof the desire stay stable over time, injury doesn't occur. Dig tunnel within the steady rock to confirm the soundness route in safety conditions within the straightforward support conditions. once cemented filling of gob, the filling body of will give sturdy support to superjacent strata and mitigate and limit the overburden collapse destroyed. once separation the lower strata movement and get in touch with with the filling body, can forestall the superjacent strata of the game to some extent, once the superjacent strata contains a higher lithology, excavation special filling route within the superjacent strata will stay stable for an extended time.

- First weight and periodic weight in mining stope. once victimisation caving mining technique, structural shaped by fissure Zone rock can expertise "stable - unstable - once more stable," within the periodic weight stage, this alteration has sure regularity. within the course of periodic weight, rock can expertise 2 processes of that the comparatively stable and vital movement. during a comparatively stable stage, vary of motion rock beam is tiny. the impact on the face mine pressure isn't obvious. once victimisation special filling route doing filling operations in fill mining, is that the use of a comparatively stable stage in rock beam, now the movement of superjacent strata has less impact on face. as a result of the recent roof supported by coal and also the filling body, there's now not a fracture instability, however solely slowly sinking. Roof is often during a state before initial pressure once use similar collapse mining. once filling body has sure strength and accumulate at the mined-out space, filling body and also the collapse of the waste rock has been operating along, will block the intensity of the roof within the vital exercise part. Cemented backfill semipermanent stability, semipermanent effective management of surface subsidence, cemented backfill has semipermanent stability, and may effective management of surface subsidence for long, give a safer atmosphere for Panel jobs.

- The feasibleness of a special filling route once has filling jobs. Special filling route drilling is organized within the higher gob. Filling suspension transportation strategies within the borehole is employed by a mixture of gravity and pressure transport, downward movement of suspension in borehole has less resistance, combined with the action of gravity, the suspension in borehole flow a lot of simply. The discharge port of filling material is found higher than the gob, in keeping with the flow vary of filling material outflow from every borehole, make sure the scope of filling cross once layout filling drilling. in keeping with the arrangement of drilling and also the website expertise, we will see a brand new filling system is crammed with filling material in gob. victimisation high concentrations of cemented filling technology within the new filling system, filling suspension dewatering controlled at intervals third, cement essentially eliminated with dehydration loss. in keeping with the length of the seam dip and panel, etc., applicable changes to the amount of drilling and drilling direction, filling body higher able to choose the highest, thereby up the standard of the filling and filling body strength, that makes the new filling technology appropriate for various mining conditions.

MINING TECHNOLOGY OF GOB FILLING VICTIMISATION SPECIAL FILLINGROAD

Composition and technology of filling system

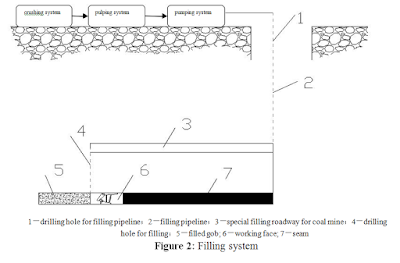

Because high concentration cemented filling are the developing direction of the coal backfill mining, the mining of gob filling victimisation special filling route selects this technology. The filling system in the main includes four main components: gangue crushing system; batching and pulping system; pumping system and filling system of the operating face. The system composition is shown in figure two. The stuff that is crushed by crushing system to attain the dimensions demand and also the cementing material which has cement area unit mixed to arrange the filling suspension. the bottom gas station and underground filling operating face area unit connected through a drilling hole for filling pipeline; the pumping system will improve the system’s filling ability. The suspension enters into the special filling route by filling pipeline and eventually pours into the gob by drilling hole for filling.

Productivity analysis

Supposing that the length of the nearly horizontal operating face is one hundred meters and also the operating face’s periodic weight length is twenty five meters with the caving mining technique, the designed stowage interval is fifteen meters for security reasons; the operating face adopts the high concentration cemented filling; the mining operating face and filling operating face each adopt “three eight system”, that's 2 teams for mining and filling and one cluster for overhaul. The operating face’s mining height is three meters; in keeping with China's current largest filling ability 150m3/h to calculate, 2400 cubical meters of area is crammed in sixteen hours each day and also the daily filling length is eight meters. as a result of the special filling route is employed for filling, coal mining and filling operations area unit parallel to every different and don't influence one another, and also the filling time is properly multiplied to create that the filling work will furthest meet the wants of the length of operating face advancing. The mining operating face adopts “three eight system” and there area unit 2 teams for mining. as a result of the length of operating face is brief, each cluster will end cutting five knives of coal and also the daily footage is eight meters, which may meet the wants of the entire mining and filling. the majority density of coal is one.35t/m3; the daily coal output is 3240t; the operating days is 330 each year; the annual coal output will reach 106.92万t[10]. The output is way over the domestic existing filling operating face’s output, thus it will bring wealthy and generous profit reciprocally for the enterprise.

Gob filling mining of high coal caving

The existing high coal caving backfill mining adopts a partial filling technique to manage roof and tunnel deformation and establish a decent operating atmosphere within the method of high coal caving mining. The universal downside of those techniques is that the filling body is simple to be stricken by the following operating face mining and there's no adequate assurance within the long -term strength and dominant surface subsidence is weak. These techniques for the highest coal caving operating face will meet the precise needs of the operating face, however to be precise, it can't be considered the highest coal caving backfill mining. However, the filling technique of gob filling victimisation special filling route is employed in gob filling mining of the highest coal caving. once the special filling route is employed for the highest coal caving, the filling body will fully fill the gob and support the roof powerfully and scale back the ignition and improve the roof pressure. The backfill drilling hole is used because the excretion gap to boost the operating face’s ventilation and mud condition.

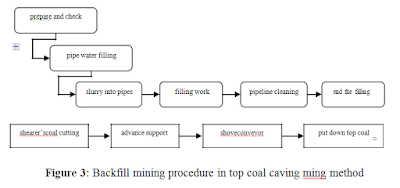

Because the special filling route is found within the stable strata within the roof, that isn’t conflict with the highest coal caving, {the high|the highest} coal caving operating face is strip-mined in keeping with the standard technique of top coal caving mining. the most method of the highest coal caving backfill mining victimisation the special filling route is that: crush and preparate suspension for filling preparation; in keeping with the mine production standing, the suspension that meets the wants once tests is transported into the pipeline within the filling operating face. The gob seems once the shearer cuts the coal within the operating face; once the strip-mined strata is stable or it's appropriate to backfill between 2 periodic weightings, the gob are crammed. With the filling work lasting, the instrumentality and waste within the filling operating face area unit cleansed at any time and also the gob filling result is dynamicly monitored and punctually replied by professionals. The concrete filling method is shown in Figure3.

CONCLUSIONS

- Mine mining of the gob cemented filling victimisation the special filling route is that: mammary gland a tunnel within the stable stratum higher than the operating face; drill holes within the route floor; backfill the operating through the holes.

- Because there area unit stable strata higher than the cemented filling operating face, the special filling route is placed in it. The high concentration cementation filling suspension contains a sure flow vary, thus it will fully fill the gob. thus it's possible in theory of backfill mining victimisation the special filling route.

- Strictly speaking, the present high coal caving backfill mining can’t meet the backfill mining technology. once the special filling route is employed for the highest coal caving of gob high concentration cementation filling, the filling body will fully fill the gob and support the roof powerfully and scale back the ignition and improve the roof pressure; the mining technology will exchange the coal with the gangue and could be a backfill mining technology of the highest coal caving during a real sense.

- When the special filling route is employed for the filling mining and “three eight system” is adopted, 1.0692 millions loads of raw coal is made in 330 days; it will nicely improve the output of the operating face and has great economic benefits.

REFERENCES

- Li Yang, Yang Bao-gui. Stowing Mining Technology Development and Classification of Chinese Modern Coal Mine[J]. Coal mining Technology, 2011,05:1-4.

- Yang Bao-gui, Cui Xi-min, Sun Heng-Hu, Kong Ling-biao, KONG Xiang-yi. The feasibility research of mining damage controlling by gob cement backfill in coal mines[J]. Journal of China Coal Society, 2000,04:361-365.

- Zhang Xin-guo, Jiang Xing-yuan, Jiang Ning, Shi Jun-wei, Li Yang-yang. Research and application of coal gangue paste packing in Daizhuangmine[J]. China Mining Magazine, 2012,04:82-86.

- Zhai Qun-di, Zhou Hua-qiang, Hou Chao-jiong, Guan Ming-liang. Discussion on mining technology with paste backfilling in mine[J]. Coal Science and Technology, 2004,10:67-69+73.

- Wang Guan-dong, Dong Feng-bao. Technology and application of high efficient mechanized backfill mining to fully mechanized long wall mining face in ZhaizhenMine[J]. Coal Science and Technology, 2008,01:15-16.

- Huang Yu-cheng, Sun Heng-hu, Shi Zhao-bing, Han Feng-xin, Long Yan-chun. Discussion on feasibility of coal mining under building structures with like gypsum material back filling[J]. Coal Science and Technology, 2003,10:51-53+39.

- Feng Guang-ming, Sun Chun-dong, Wang Cheng-zhen, ZHOU Zhen. Research on gob filling methods with super high-water material[J]. Journal of China Coal Society, 2010,12:1963-1968.

- Sun Heng-hu, Huang Yu-cheng, Yang Bao-gui. Contemporary Cemented Filling Technology[M]. Beijing: Metallurgical Industry Press, 2002.

0 Komentar:

Post a Comment